Efficiency is crucial for any organization, be it small or large Each business leader strives to achieve more – more sales, more revenue – with fewer resources , less wastage, and reduced costs.

Human resource management, material supplies, work stations, equipment, and production processes are all managed and scheduled by production planning and control. It determines the most cost-effective technique to produce final product while meeting production demand.

The basis of each industrial operation is production planning and control. Material forecasting, master production scheduling, long-term planning, demand management, and other features are included. The planning process begins with a product’s demand forecasts. The production plan is produced using the projected data and internal resources available.

The daily production planning process includes defining the series of your production, generating a production timeline, allocating your resources, and evaluating your production strategy.

In manufacturing business, what function does production planning and control play?

Making sure that production resources are available when needed is a key element of production planning and controlling. To keep production running smoothly, materials, equipment, and personnel must all be available at the appropriate times. It is the most important aspect of a manufacturing company.

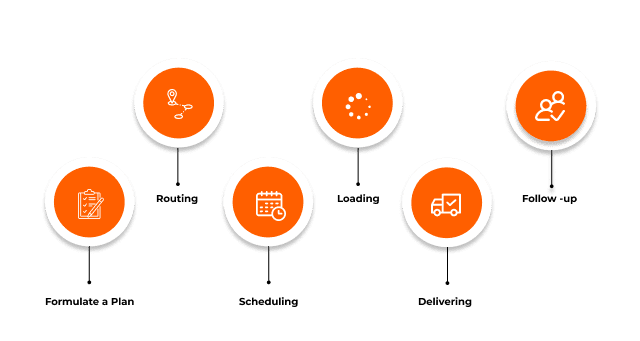

The following steps comprise production planning and control:

1. Formulate a plan –

Planning dictates what will be produced, who will create it, and how it will be produced. It creates a production plan that includes manpower, equipment, work areas, and material requirements.

2. Routing –

The path raw materials take within the factory is determined by routing. Raw resources are turned into finished goods using the sequence.

3. Scheduling –

The emphasis in the schedule is on “when” the activity will be performed. Its goal is to make the most of the time allotted for the operation’s completion.

4. Loading –

The amount of work loaded against equipment or employees is referred to as loading. The whole time required to complete a new task is added to the time allotted for the machine or workstation.

5. Delivering –

The release of orders and accompanying instructions is known as dispatching. It follows the instructions for routing and scheduling. This stage ensures that all of the necessary items are in place for the personnel to complete their tasks.

6. Follow-up –

Continual follow-up, also known as expediting, is a process for locating faults, imperfections, bottlenecks, and gaps in the manufacturing process. The team measures the actual performance from start to finish and compares it to the expected performance in this stage.

Smartsheet for production planning: Putting the right technology in place:

Many manufacturing companies still plan using paper and spreadsheets, which is ineffectual, time consuming, and inaccurate. Staying competitive in the production planning industry needs reliability and efficiency.

How Smartsheet enhances your manufacturing with production planning.

Keep track of your machine's output -

Find a system that allows staff to analyze real-time machine usage statistics and take immediate action to improve uptime.

Boost precision -

Making educated judgments and getting it wrong might have disastrous consequences. MRP (materials requirement planning) necessitates precision in data related to sales orders, due dates, and predictions, which Smartsheet can supply.

Increase the rate of production -

Using software like Smartsheet to streamline procedures improves uptime and allows facilities to respond to increased demand.

Stakeholders should share information -

Both internal and external stakeholders require a reliable means of communicating and identifying chances for development. Select a technological platform that allows you to share information rapidly and transparently.

Make manufacturing schedules -

Solutions like Smartsheet make it easy to manage supply chain communication. Production calendars and reports help manage scheduling and forecasting by reducing inventory and eliminating flow disruptions.

Simple and candid to use -

Smartsheet features an effective platform that can be tailored to the work at hand, decreasing the obstacle for those who aren’t tech-savvy.

Automate the process -

Choose technology that helps teams to automate workflows and streamline day-to-day operations, saving time and keeping your team connected and informed.

Collaboration -

collaborating with your team is simplified with the use of Smartsheet. You can automate emails and notifications to your team as per requirements.

Smartsheet streamlines supply chain management and optimizes production efficiency, resulting in increased revenue growth

Implementation and Work schedules of Productions -

Smartsheet allows you to manage timetables and timelines in a variety of formats, including calendar and Gantt charts. It also makes it easier to keep track of important facts along the road, which improves responsibility.

Production process -

Smartsheet helps to prevent supply chain disruptions by streamlining the end-to-end process. It lets you keep everyone on the same page and improve cooperation by allowing you to share documents, information, and comments in one location.

Control of Compliance -

Track tasks by sequence, priority, and status using Smartsheet, and advance complex programs at scale. You may automate projects or spend approval and change requests, maximizing efficiency.

Are you looking for a more efficient way to manage your production planning? You've come to the right place.

Ignatiuz's smartsheet project management tool: the most efficient method for production planning

One of the clients of Ignatiuz had been previously maintaining track of all the data on a spreadsheet, which was insufficiently robust and time-consuming to maintain on a regular basis. It was difficult to keep track of all of the manufacturing data in a spreadsheet.

Ignatiuz further assisted the customer in streamlining, standardizing, and integrating Systems, Applications, and Products (SAP) with Smartsheet, and supported industrial businesses with process and control improvements. Smartsheet in a business framework helps in speeding up company so you can make smarter decisions faster.

Ignatiuz integrated in SAP and Smartsheet to create a finite Smartsheet production schedule from an infinite SAP production schedule. With Ignatiuz’s assistance, the customer was able to streamline the trial process, consolidate data from many tests, and set production schedules using Smartsheet.

The Smartsheet platform allowed the customer to collaborate, manage, and report on work in real-time, automate workflows, and deploy new processes at scale. Smartsheet has now established a connection with SAP and is retrieving all the necessary data. To ensure that all groups are aware of their duties and may begin posting comments on the Smartsheet, infinite data is reduced to a limited schedule. Due to the initial increased automation and collaboration features, as well as the agility with which users can acquire and work on their data, Smartsheet presently allows users to work efficiently.

By recording each aspect of the production process and control, Ignatiuz was able to track, verify, and facilitate the product’s delivery. The solution technique was effective and saved a significant amount of time.

Do you want to save time and be more efficient by automating your production planning process? Then contact us right now. Go through our, case study for more details.